Lighting Up Bone Repair

Researchers led by TMDU fabricate a material that will aid bone healing, help medical practitioners clearly assess the full damage to bones after an injury, and clarify probable patient outcomes

Tokyo, Japan – Bone repair wasn't generally successful until the late 1800s. Until then, there were few options to repair major bone damage. Most materials don't have the functionality of bone and don't support blood vessels growing through them. Repair materials such as clay were commonly used yet often failed. In 1892, medical practitioners started using gypsum—calcium sulfate—as the first effective bone substitute material. Bone repair is much more straightforward and less risky these days, but repairing large-scale bone damage remains challenging.

Medical practitioners today use octacalcium phosphate—OCP—as a substitute bone material. It's a precursor of bone tissue and a logical choice for bone repair. However, medical practitioners may not be able to unambiguously assess the complete extent of bone damage by X-ray analysis. This may hinder their ability to accurately predict recovery timelines and other prognoses for patients.

In a study recently published in Communications Chemistry, a team led by researchers at Tokyo Medical and Dental University (TMDU) incorporated a fluorescent molecule—pyromellitic acid—into OCP. When used in clinical practice, this advanced modification to OCP will improve diagnostic analyses and predictions of therapeutic outcomes.

"We incorporated pyromellitic acid by a hydrolysis reaction with dicalcium phosphate dihydrate," explains Taishi Yokoi, lead author. "Analytical characterization and computational analyses confirmed that we prepared our target material."

Their synthetic approach avoided formation of undesired salts—calcium carboxylates—that would otherwise hinder the full functionality of pyromellitic acid. By carefully tailoring the pH and pyromellitic acid concentrations during synthesis, the researchers were able to optimize incorporation of pyromellitic acid into OCP.

"We found that 81% of the monohydrogen phosphate in OCP was replaced by pyromellitic acid," says senior author Masakazu Kawashita. "This is important for pyromellitic acid to help connect different inorganic layers into an intact whole, and facilitate complete repair."

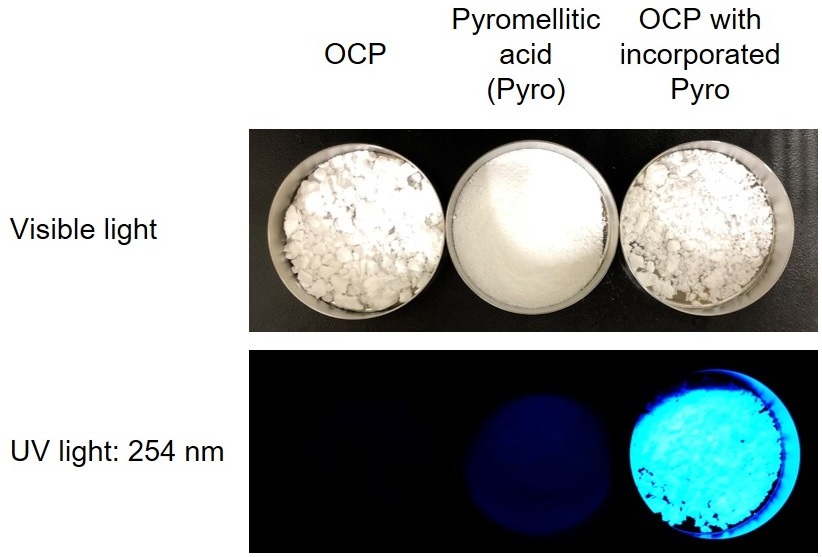

The researchers' improved bone replacement material was bright blue, much brighter than pyromellitic acid is when it is not mixed with bone precursors. This opens up obvious possibilities for real-time visual analysis, and will help medical practitioners predict the time course of patient recovery and other diagnostic outcomes.

Tokyo, Japan – Bone repair wasn't generally successful until the late 1800s. Until then, there were few options to repair major bone damage. Most materials don't have the functionality of bone and don't support blood vessels growing through them. Repair materials such as clay were commonly used yet often failed. In 1892, medical practitioners started using gypsum—calcium sulfate—as the first effective bone substitute material. Bone repair is much more straightforward and less risky these days, but repairing large-scale bone damage remains challenging.

Medical practitioners today use octacalcium phosphate—OCP—as a substitute bone material. It's a precursor of bone tissue and a logical choice for bone repair. However, medical practitioners may not be able to unambiguously assess the complete extent of bone damage by X-ray analysis. This may hinder their ability to accurately predict recovery timelines and other prognoses for patients.

In a study recently published in Communications Chemistry, a team led by researchers at Tokyo Medical and Dental University (TMDU) incorporated a fluorescent molecule—pyromellitic acid—into OCP. When used in clinical practice, this advanced modification to OCP will improve diagnostic analyses and predictions of therapeutic outcomes.

"We incorporated pyromellitic acid by a hydrolysis reaction with dicalcium phosphate dihydrate," explains Taishi Yokoi, lead author. "Analytical characterization and computational analyses confirmed that we prepared our target material."

Their synthetic approach avoided formation of undesired salts—calcium carboxylates—that would otherwise hinder the full functionality of pyromellitic acid. By carefully tailoring the pH and pyromellitic acid concentrations during synthesis, the researchers were able to optimize incorporation of pyromellitic acid into OCP.

"We found that 81% of the monohydrogen phosphate in OCP was replaced by pyromellitic acid," says senior author Masakazu Kawashita. "This is important for pyromellitic acid to help connect different inorganic layers into an intact whole, and facilitate complete repair."

The researchers' improved bone replacement material was bright blue, much brighter than pyromellitic acid is when it is not mixed with bone precursors. This opens up obvious possibilities for real-time visual analysis, and will help medical practitioners predict the time course of patient recovery and other diagnostic outcomes.

Images of OCP, pyromellitic acid and OCP with incorporated pyromellitic acid under visible and UV light (254 nm).

OCP with incorporated pyromellitic acid showed a brilliant blue emission under UV light owing to the incorporated fluorescent molecule. Incorporation of organic molecules into OCP imparted new functions, which could enable the development of novel functional materials for biomedical applications, especially bone repairing.

OCP with incorporated pyromellitic acid showed a brilliant blue emission under UV light owing to the incorporated fluorescent molecule. Incorporation of organic molecules into OCP imparted new functions, which could enable the development of novel functional materials for biomedical applications, especially bone repairing.

"Our improved OCP has distinct advantages over conventional bone repair materials," explains Yokoi. "We're optimistic that our material can quickly overcome regulatory hurdles and find use in dental implants, bone fractures, and other challenging surgical applications in the coming years."

###

The article, "Incorporation of tetracarboxylate ions into octacalcium phosphate for the development of next-generation biofriendly materials," was published in Communications Chemistry at DOI: 10.1038/s42004-020-00443-5Summary

Researchers from TMDU fabricated a bright fluorescent bone replacement material, based on a precursor to bone tissue that’s common in medical practice. The material will be useful in bone repair and dental implants, and facilitate bone regrowth while providing new diagnostic and prognostic functionalities.

Correspondence to

Taishi Yokoi,Associate Professor

Department of Inorganic Biomaterials,

Institute of Biomaterials and Bioengineering,

Tokyo Medical and Dental University (TMDU)

E-mail:yokoi.taishi.bcr(at)tmd.ac.jp

*Please change (at) in e-mail addresses to @ on sending your e-mail to contact personnels.

Department of Inorganic Biomaterials,

Institute of Biomaterials and Bioengineering,

Tokyo Medical and Dental University (TMDU)

E-mail:yokoi.taishi.bcr(at)tmd.ac.jp

*Please change (at) in e-mail addresses to @ on sending your e-mail to contact personnels.