Zirconia ceramics: promising restorative material offers strength and aesthetics

Masanao Inokoshi,

Assistant Professor of Department of Gerodontology and Oral Rehabilitation at TMDU

After I obtained my DDS degree in 2006, I started my first PhD training at TMDU. In 2010, I won a Flemish scholarship for Japanese students and moved to the University of Leuven (KU Leuven) in Belgium to conduct my second PhD training. In Leuven, I studied under Prof. Bart Van Meerbeek who is head of the KU Leuven BIOMAT research cluster. I obtained my second PhD in 2014 from KU Leuven.

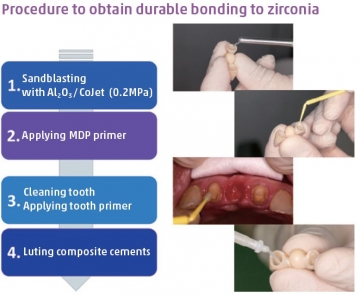

At KU Leuven BIOMAT, my research topic was dental zirconia ceramics. Zirconia ceramics have become increasingly popular in dentistry, thanks to their aesthetic and biocompatible properties as compared to conventional metal-based restorations. Although zirconia has been applied in dentistry, scientific background for zirconia is still lacking. Previously, we focused on the resistance to aging and the bonding strategy of zirconia ceramics. We clarified that zirconia is aging-resistant as a dental restorative material.Regarding bonding strategies for zirconia ceramics, combined mechanical (alumina sandblasting) and chemical (MDP containing primer application) pre-treatments are important to obtain durable bonding to zirconia. Our paper, published in the Journal of Dental Research, is the first to report on having conducted meta-analysis regarding bonding efficacy to dental zirconia (J. Dent. Res., doi: 10.1177/0022034514524228).

More recently, highly translucent zirconia is booming in dentistry. Compared to conventional zirconia ceramics, highly translucent zirconia is more aesthetically pleasing and can be used in full-zirconia restorations. Now we are focusing on this new material to clarify its properties. We are striving to create novel aesthetic, strong and aging-resistant highly translucent zirconia ceramics, as well.

1. Sandblast the zirconia surface at low pressure (0.2 MPa) using Al2O3 particles of up to 50 μm in size; alternatively tribochemically silica sandblast/coat (CoJet, 3M ESPE) using silica-coated Al2O3 particles of up to 50 μm in size. 2. Apply MDP-containing primer to the sandblasted surface. 3. Clean tooth and apply tooth primer if necessary. 4. Apply luting composite cements and light-cure them using light-curing unit.